No, I’m not talking about the dentist and his biker chick. I don’t get that one, but I absolutely respect their feelings for one another.

No, I’m talking about a new relationship that I’m just starting to recognize. It’s the relationship between the amount of downward pressure exerted on fabric when the needle pierces it and forms a stitch.

I have machines that will not free motion quilt. They do beautiful work when there’s a stitching foot on them. But, they WILL NOT free motion quilt. The only difference between piecing and free motion quilting, if you can’t drop the feed dogs, which most of my machines won’t do, is basically the foot. Hmmm. Something about changing the foot prevents the stitch from forming. And, I haven’t been able to figure it out.

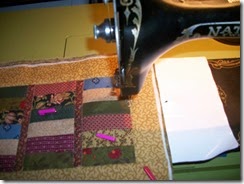

I was having the same problem on the National Two Spool sewing machine. Stitches just wouldn’t form without the sewing foot.

Okay, so let’s talk for a second about free motion feet for machines that take Griest feet. Griest feet don’t attach like regular sewing feet, so modern darning feet won’t fit them. But, I found this very smart lady who has made a Griest foot out of a paperclip. Brilliant! There is an official darning foot for the machine and it works nicely, but it’s kind of impractical.

It’s a piece of copper wire. The spring side to the left goes over the needle and the hook on the right goes over the needle set screw. It works well, but it has a limited shelf life as that copper wire is only going to spring up and down so many times before it breaks. So, I don’t use it often, but it’s a nice attachment to have.

But, my paperclip foot was easy to make and it’s more practical. And, if I break it, it won’t cost $15 to replace. When I loaded it on the machine, it kind of floated above the fabric. And, stitches wouldn’t form. The fabric would grasp the needle and as the needle rose, the fabric would rise just a tiny bit and the stitch would not form. So, I bent the foot so that it presses down on the fabric hard. Stitches immediately started to form, but it caught on every seam. Can’t have that. So, I straightened it out just a bit so that it applies just a little less downward pressure on the fabric and stitches kept forming and the foot glided over the fabric seams without any trouble. A delicate balance based on just fiddling with it.

Okay, so I don’t yet fully understand the relationship between the pressure exerted downward on the fabric and the formation of a stitch, but I suspect that if the fabric can lift up with the needle when the needle rises, that causes the thread loop being formed by the upper thread to rise as well, and prevents the hook from being able to grasp the thread and pull it around for the stitch. Normally the fabric would grasp that thread that’s forming the loop and keep it from rising back up at the same rate as the needle. But, if the fabric itself is moving, then that loop is going to rise with it.

That makes sense when I think of the machines that won’t FMQ. There is that little lift in the fabric because the foot doesn’t hold it down securely. I’m excited to try this theory on other machines; especially machines where I’m not using the darning foot that was provided with the machine. I want to try the manufacturer supplied darning feet and see if that makes a difference. I’ll let you know if it holds true. I also have other Griest machines that I’d like to try this on.

Everybody have a great Tuesday. I’m so busy with Quilt Guild business this week that I haven’t had time to sew a stitch.

Lane

5 comments:

My, my, you are so above me. I'm not really sure I know what you are talking about. Told you, you know more about sewing than I ever did. That is why you have my machines. Hope you get it together, like you want it, before Guild. lum

I've got the same questions about presser foot pressure, so this is a really interesting post. It surprises me that slight variations in pressure/location of foot above fabric can make such a huge difference.

Lane, you are correct in that if the fabric isn't held down as the needle starts to rise, the thread will follow with it and not form a stitch. It's called "flagging". If you watch a darning or hopping foot, it starts to raise *just* after the needle starts to raise, giving the hook time to catch the thread. If you want to free motion on a machine that doesn't accept a darning foot well or doesn't have one, just use your regular straight stitch foot. You don't have to cover or drop the feed dogs either, just set the stitch length to zero and lessen the presser foot pressure some. I've been quilting this way for years on a 15 class end loading clone that doesn't like any type of quilting foot.

Cari

karry_smith2003@yahoo.com

Cari-- thank you so much! I looked for a while yesterday for information on how stitches are formed because I'm having the same issue as Lane. I think that if my straight stitch is forming well, then the presser foot pressure is the next thing to consider, and your description of how you use a vintage machine to quilt confirms this. Now, I'm dying to try it.

I understand the issues well. Just the difference between sewing thickness of fabrics on my Viking Saphire vs my Viking Rose. You would have thought a sailor was in my sewing room last night. The saphire is fine for cotton but nothing else. Grrr. And the sapphire freezes up when I try to do free motion also

Fun

Post a Comment